When brewing German and European-style lagers, precision and yeast selection are critical. In this edition, we take an in-depth look at FERMOLAGER Munich Heritage — the latest addition to AEB’s lager portfolio. Originating from Munich, Bavaria, this versatile strain offers brewers a reliable foundation delivering lagers with a signature crispness and clean flavour profile while naturally enhancing malt character.

Sitting between ultra-neutral strains and more expressive lager yeasts, FERMOLAGER Munich Heritage achieves high clarity through medium-high flocculation and delivers a clean flavour profile with minimal ester, sulphur, and diacetyl production. These desirable traits stem from its unique metabolic regulation, particularly in pathways associated with amino acid biosynthesis and off-flavour control.

In this article, we explore best practices for fermentation with FERMOLAGER Munich Heritage, delve into the biochemical mechanisms behind its remarkably low diacetyl production, and explain why this strain stands out as a robust, low-intervention house yeast for modern lager brewing.

Diacetyl Production

Diacetyl is a by-product of valine biosynthesis, a metabolic pathway in which yeast produces valine, an essential branched-chain amino acid (BCAA) used to build proteins and enzymes for growth, metabolism, and stress response. During this process, α-acetolactate is naturally produced as an intermediate. When the pathway is well-regulated, α-acetolactate remains inside the cell and is efficiently converted to valine. However, under certain conditions—such as nutrient deficiency, temperature stress, or inefficient feedback control—α-acetolactate accumulates inside the cell. Due to the semi-permeable nature of the yeast cell membrane, this surplus can leak out into the wort, where it oxidizes into diacetyl.

Boiled down, high intracellular concentrations, stemming from weak feedback inhibition in the valine biosynthesis pathway or environmental stresses (such as low oxygen or nutrient deficiency), drive excess α-acetolactate to diffuse out of the cell and oxidize into diacetyl.

What Is Feedback Control in Yeast Metabolism?

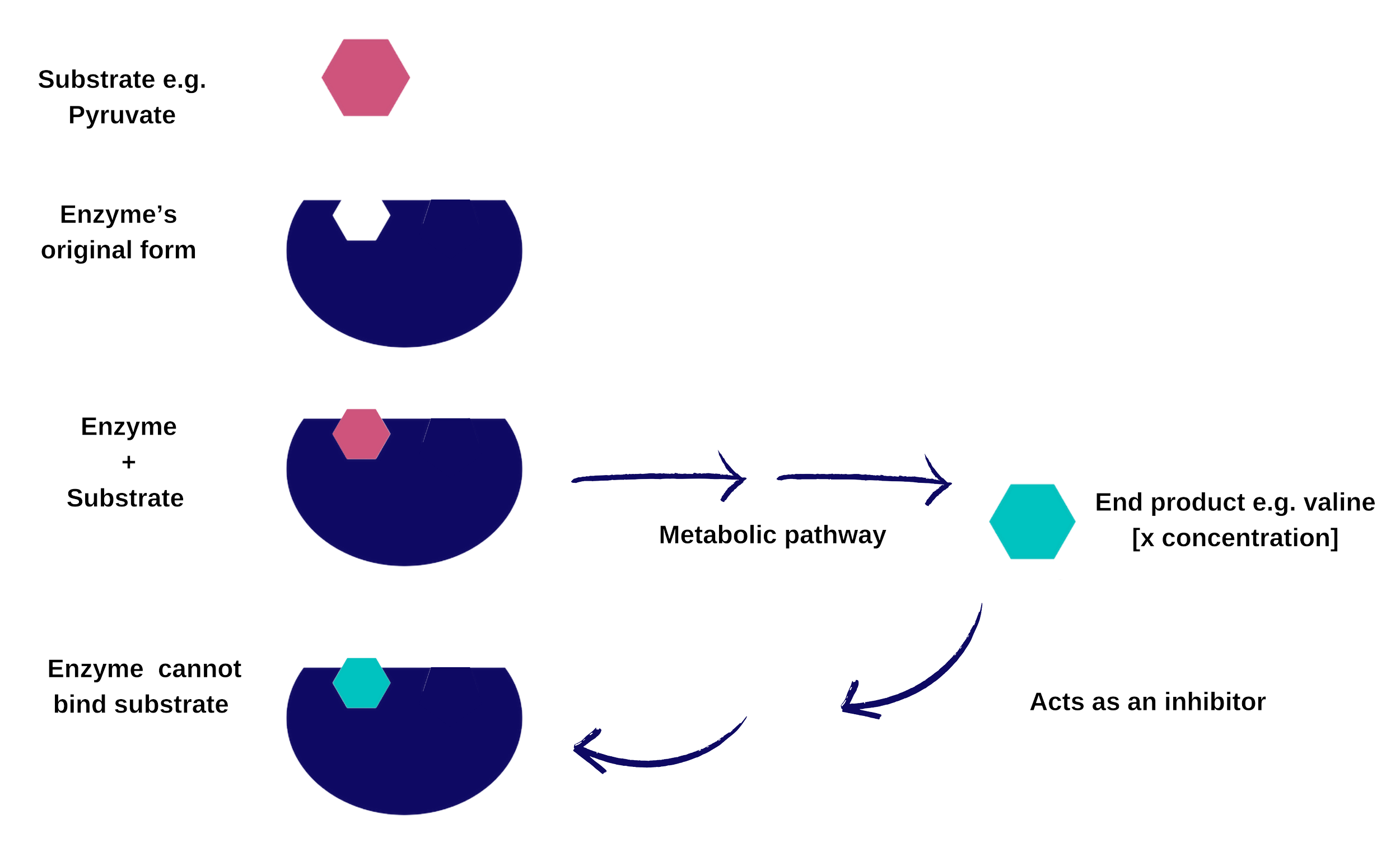

Feedback control (or feedback inhibition) is a natural regulatory mechanism used by cells, including yeast, to control how much of a compound they produce. Feedback inhibition is like a biological version of a PID controller (Proportional-Integral-Derivative). In a PID system, the controller constantly monitors the output (e.g. temperature, pressure, or flow rate) and adjusts the input accordingly to maintain a stable state. Similarly, in yeast, feedback inhibition monitors the internal concentration of end products like valine and "adjusts the flux" through the biosynthetic pathway by turning off or downregulating key enzymes. When this regulation is impaired (like a poorly tuned PID loop), the system overshoots, producing excess intermediates like α-acetolactate.

In yeast, when there's enough valine inside the cell, the first enzyme in the valine biosynthesis pathway is bound and inhibited. This prevents the yeast from making too much, which conserves energy and avoids the build-up of unnecessary intermediates, like α-acetolactate, which can lead to diacetyl.

What Causes Inefficient Feedback Control?

1. Genetic Variation in Yeast Strains

Some yeast strains are naturally poor at regulating this pathway. Their enzymes may not respond strongly to valine, so the pathway keeps running even when it shouldn't, leading to excess α-acetolactate.

2. Environmental Stress

When yeast cells are under stress — from low oxygen, temperature extremes, or nutrient deficiencies — they may lose metabolic control. Stress can impair enzyme function or gene regulation, reducing the yeast’s ability to shut down unnecessary pathways.

3. Rapid Fermentation or High Gravity Brewing

In high-speed or high-sugar fermentations, yeast may prioritize rapid growth over fine-tuned regulation, producing more α-acetolactate than they can process efficiently.

Why Fermolager Munich Heritage Produces Lower Levels of Diacetyl

FERMOLAGER Munich Heritage possesses a tightly regulated valine biosynthesis pathway and efficient intracellular feedback systems. These characteristics significantly reduce α-acetolactate accumulation and leakage, leading to lower diacetyl formation during fermentation.

Moreover, Munich Heritage displays strong diacetyl reductase activity. This allows the yeast to not only prevent excessive diacetyl from forming but also to rapidly reabsorb and metabolize any diacetyl that does develop. It converts diacetyl into flavour-neutral compounds like acetoin and 2,3-butanediol, which do not contribute to off-flavours.

This dual capability—both preventing diacetyl formation and effectively cleaning it up—ensures a crisp, clean lager profile with minimal risk of buttery or sulphury notes, making FERMOLAGER Munich Heritage a reliable choice for brewers seeking high flavour precision in traditional and modern lager styles.

Effective Diacetyl Control

Although Fermolager Munich Heritage produces minimal diacetyl, brewers should still conduct a diacetyl rest at 14-16°C near fermentation completion to ensure a clean profile.

Low Sulphur Compounds Production

Sulphur compounds—particularly hydrogen sulphide (H₂S)—are natural by-products of the yeast’s sulphur assimilation pathways, often arising when cells are under metabolic stress. FERMOLAGER Munich Heritage produces exceptionally low levels of these unwanted sulphur aromas, due in large part to two key factors. First, the strain demonstrates optimized nitrogen uptake, meaning it efficiently metabolizes available nitrogen sources. This reduces metabolic stress on the yeast and, in turn, limits the overproduction of sulphur compounds. Second, Munich Heritage exhibits controlled sulphur pathway activity, with notably low expression of sulphite reductase enzymes, which are directly responsible for generating H₂S. Together, these features ensure a cleaner fermentation profile with minimal risk of sulphur off-notes.

Click here to read our previous article on sulphur compounds production.

Low higher alcohols and esters production

FERMOLAGER Munich Heritage produces low levels of esters and higher alcohols due to a combination of genetic, metabolic, and environmental factors. As a Saccharomyces pastorianus strain specifically selected for traditional German-style lager brewing, it is genetically predisposed to produce a clean and neutral flavour profile. This includes reduced activity in metabolic pathways responsible for ester and higher alcohols formation, such as the Ehrlich pathway and alcohol acetyltransferase reactions.

Additionally, its optimal fermentation temperature range (10–14°C) naturally slows down yeast metabolism, further limiting the synthesis of these compounds. Fermolager Munich Heritage also demonstrates efficient nitrogen and sugar utilization, which helps prevent overflow metabolism that typically leads to higher alcohol production. Because it performs well under standard lager fermentation conditions and is resilient to environmental stress, it avoids triggering stress-induced pathways that would otherwise elevate ester and fusel levels. Together, these factors contribute to the strain’s ability to produce clean, crisp lagers with minimal fruity, solvent-like, or warming notes.

For a deeper understanding of how esters and higher alcohols are produced through the Ehrlich pathway, read our article on FERMOPLUS® AromaGlow—a nutrient specifically formulated to boost these flavour-active compounds by stimulating the Ehrlich pathway.

Malt accentuating capacity

Malt flavours in lagers are often subtle compared to ales, and they can be easily overshadowed by fruity or phenolic yeast notes. Because Munich Heritage produces minimal fruity esters, the malt’s sweetness and flavour aren’t muddled by notes of banana, apple, or solvent that would otherwise pull the palate in a different direction. Because it produces minimal diacetyl, the malt isn’t masked by a buttery film – instead, the finish remains crisp, letting the dry maltiness or residual sweetness be appreciated cleanly. And because it keeps sulphur in check, the malt aroma isn’t lost under a rotten-egg or vegetal smell (which, even when mild, can reduce the perception of malt sweetness and fullness). The net effect is that beers fermented with this yeast tend to have a “malt-forward” impression: the drinker will immediately notice the malt flavor (whether it’s the delicate pilsner malt taste in a Helles, or the rich caramelized malt depth in a Dunkel), with very little in the aroma/flavour to distract from that experience.

Another subtle way Munich Heritage accentuates malt is through its moderate attenuation. With ~78–80% apparent attenuation, it doesn’t ferment every last dextrin, especially in mashes that are designed to leave some dextrins. This means the finished beer can retain a touch more body and sweetness compared to a more aggressively attenuating strain. That residual malt presence on the palate boosts malt flavor perception (since sweetness and body often enhance flavour). A drier fermenting yeast might make the beer crisper, but could also thin out the malt impact. FERMOLAGER Munich Heritage hits a sweet spot of fully fermenting the simple sugars (preventing cloying sweetness) but leaving just enough residual malt sugars to accentuate the malt backbone. In practice, brewers find beers made with this yeast have a rounded finish, not sweet per se, but rich in malt flavour and with a smooth mouthfeel.

Water Chemistry Management

Water composition plays a crucial role in defining the final flavour, balance, and mouthfeel of lager beers. Classic lager styles—especially those from brewing regions like Munich and Pilsen—are deeply influenced by their native water profiles. Adjusting mineral content allows brewers to replicate these traditional characteristics while supporting yeast health and fermentation performance. Below are key water chemistry recommendations to optimise results when brewing with FERMOLAGER Munich Heritage.

Sulphate (50-100 ppm): Soft, smooth bitterness.

Chloride (50-100 ppm): Enhances malt sweetness and fullness.

Bicarbonate (<50 ppm): Essential for light-coloured lagers.

Soft water profiles: Mimic classic regions like Munich or Pilsen.

Tip: Maintain calcium levels (~50 ppm) for yeast health and flocculation.

Maturation & Lagering Time

Traditional lagering significantly enhances the final beer’s smoothness and clarity. Lager for 2-6 weeks at 0-2°C to reduce residual VDKs, sulphur compounds, and polish flavour integration.

Why FERMOLAGER MUNICH?

Choosing FERMOLAGER Munich Heritage provides brewers with versatile brewing applications, making it suitable for a wide variety of lager styles and streamlining brewery operations. Biochemically, its metabolism is geared toward neutral flavour production – it suppresses ester formation (through limited higher alcohol production and enzyme activity), tightly regulates sulphur assimilation (preventing H₂S accumulation), and efficiently cleans up intermediate compounds during maturation.

This yeast delivers what brewers value most: clarity, consistency, and clean expression of ingredients. This strain offers a rare balance—combining remarkably low production of esters, higher alcohols, sulphur compounds, and diacetyl with medium-high flocculation and moderate attenuation, allowing it to produce crisp, well-defined lagers that highlight malt and noble hop character without interference from unwanted yeast-derived flavours such as fruitiness or sulphur. Its clean fermentation profile means less time spent on diacetyl rests or conditioning, while its robustness across 10–14 °C makes it both flexible and efficient. Whether you're brewing a Helles, Märzen, or Pilsner, Munich Heritage provides a low-intervention, high-performance solution that consistently showcases the brewer’s recipe.

Fermentation Temperature

To achieve optimal performance with FERMOLAGER Munich Heritage, maintain fermentation temperatures between 10–14°C. Cooler ranges (10–12°C) promote the cleanest, most neutral flavour profiles, while slightly warmer fermentations (13–14°C) can speed up fermentation and contribute a rounder mouthfeel. Thanks to the strain’s naturally low ester and sulphur compound production, even at the higher end of this range, off-flavour formation remains minimal.

Tank residency reduction by Fermolager Munich Heritage

FERMOLAGER Munich Heritage contributes to faster turnaround times by:

Having medium-high flocculation, allowing for faster clarification and easier yeast cropping

Performing well across 10–14°C, with warmer fermentations (13–14°C) slightly accelerating fermentation without risking off-flavours

While exact reductions in tank time depend on your specific process, brewers can expect cleaner fermentations in less time compared to more volatile or diacetyl-prone strains.

Ana Victoria Vasquez de la Peña

ana@neumaker.com.au

4 April 2025

© 2025 neumaker. All rights reserved. This article may be shared/forwarded for personal or educational purposes, provided it remains unaltered and includes proper attribution. Reproduction, distribution, or use in any other form—including but not limited to commercial purposes, republishing, or adaptation—without explicit written permission is strictly prohibited.

References

Kohlhaw, G. B. (1988). Valine, leucine, and isoleucine biosynthesis in microorganisms. In The Biochemistry of Plants (Vol. 11). Academic Press.

Krogerus, K., & Gibson, B. R. (2013). Diacetyl and its control during brewery fermentation. Journal of the Institute of Brewing, 119(3), 86–97. https://www.cibd.org.uk/media/i3xllx3x/jib-84.pdf

Preiss, R., Tyrawa, C., & Van der Merwe, G. (2017). Diacetyl metabolism and sensory impact in lager yeasts. Journal of the American Society of Brewing Chemists, 75(2), 123–130.

Smart, K. A. (1996). Yeast physiology and diacetyl removal. MBAA Technical Quarterly, 33(3), 150–154.

Umbarger, H. E. (1956). Evidence for a negative-feedback mechanism in the biosynthesis of isoleucine. Science, 123(3202), 848. https://en.wikipedia.org/wiki/Harold_Edwin_Umbarger

Yoshida, T., Furihata, X., & Nishikawa, J. (2018). High-level production of valine by expression of the feedback inhibition-insensitive acetohydroxyacid synthase in Saccharomyces cerevisiae. Enzyme and Microbial Technology, 110, 40–47. https://www.sciencedirect.com/science/article/abs/pii/S1096717617304354

Zhang, X., Wang, X., Shrestha, B., & Tan, T. (2021). Engineering of microbial cells for L-valine production. Microbial Cell Factories, 20, 181. https://pmc.ncbi.nlm.nih.gov/articles/PMC8406616/

Boulton, C., & Quain, D. (2001). Brewing Yeast and Fermentation. Wiley.

Baker, E. P., Peris, D., Moriarty, R. V., Li, X. C., Fay, J. C., Hittinger, C. T., & Rokas, A. (2022). Mitochondrial DNA and temperature tolerance in lager yeasts. Nature Communications, 13(1), 3045. https://doi.org/10.1038/s41467-022-30727-4

Gallone, B., Mertens, S., Gordon, J. L., Maere, S., Verstrepen, K. J., & Steensels, J. (2019). Origins, evolution, domestication and diversity of Saccharomyces cerevisiae lager brewing yeasts. Current Opinion in Biotechnology, 56, 169–176. https://doi.org/10.1016/j.copbio.2018.12.008

Gibson, B., & Liti, G. (2015). Saccharomyces pastorianus: genomic insights inspiring innovation for lager brewing. FEMS Yeast Research, 15(1), 1–10. https://doi.org/10.1111/1567-1364.12172

Krogerus, K., Arvas, M., & Gibson, B. R. (2013). Adaptive evolution of lager yeast under pressure: impact on fermentation performance and gene expression. FEMS Yeast Research, 13(3), 335–349. https://doi.org/10.1111/1567-1364.12040

Wang, Q., Wang, J., Tan, X., Zhang, H., & Wang, H. (2021). Construction of a brewing Saccharomyces cerevisiae mutant with improved beer flavor stability using ARTP mutagenesis. Foods, 10(12), 3057. https://doi.org/10.3390/foods10123057